CNC Milling Machining

CNC machining, our company has 3 axis CNC milling machine and 4 axis CNC milling machine and 5 axis CNC milling machine.

Can complete any structure of complex processing, we have a professional team, experienced programming engineers, production precision can reach 0.005-0.01mm error.

The parts we produce can be applied to different fields, such as aviation, new energy, electronics, artificial intelligence, medical, hardware, construction and other fields.

We will open video communication with you at the same time of production, so that you can see the production process on-site, or we can provide you with production photos and videos.

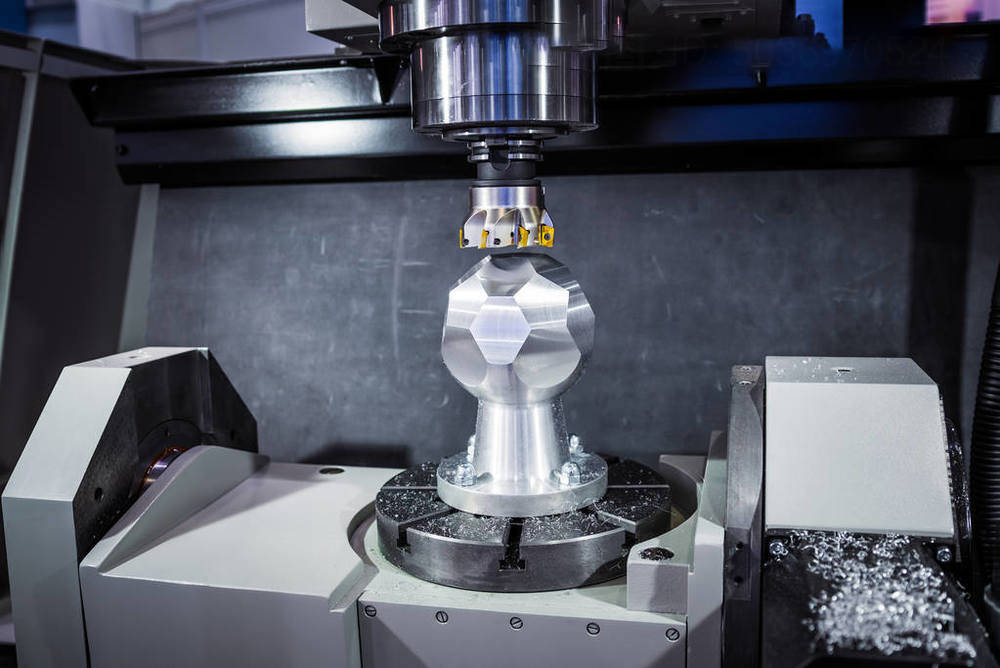

CNC Lathe Machining

Our company has multi-angle lathes, turning and milling compound, machine, and ordinary lathes, can complete the precision and complex structure of mechanical parts, cylinder, thread, grooving, turning section and other functions.

Usually our lathe to complete the cylinder and round parts, we use imported blade tools, processed parts are very bright, look very perfect, and our precision is also very high, can reach 0.005-0.01 mm.

Our feature is that there are fully automatic automatic lathe equipment, equipment can complete the clamping and turning independently, do not need technical personnel, for mass production, you can save the cost of labor, reduce the overall price

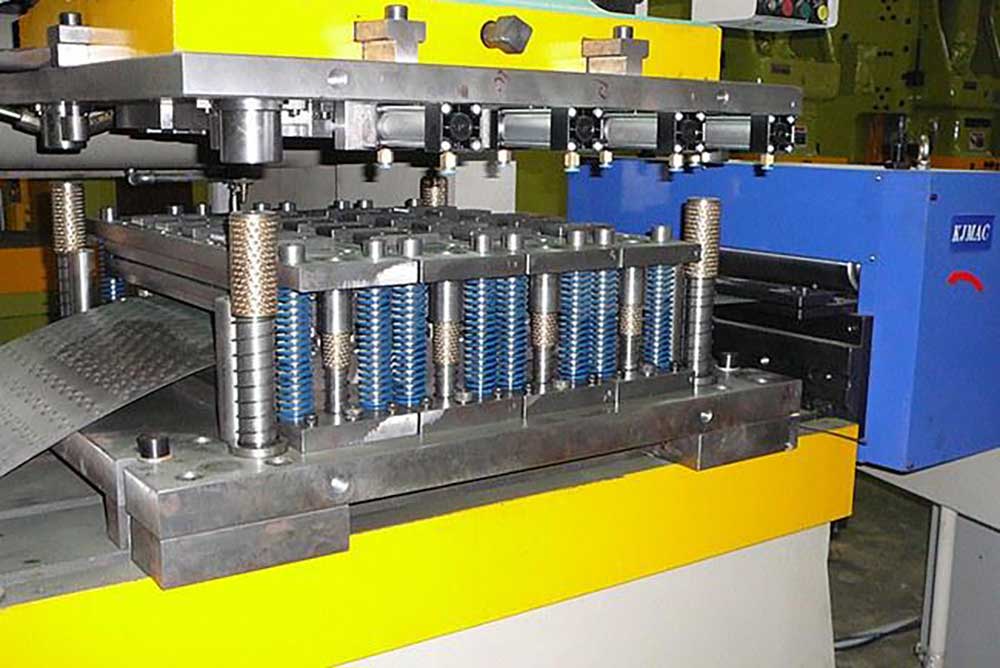

Stamping Customization

Our stamping equipment, we can do some aluminum and metal and copper stamping or stretching processing.

We have a fully automatic production line, no labor is required, so it is very cost saving, we can produce 500,000 to 1000000 products per month.

And we can produce stamping needs of our own mold, we have CNC can complete a set of production customization by ourselves, which is our huge advantage!

We can get materials from the most source material supplier, which can save a lot of costs for mass manufacturing

Laser Bending

We have high power laser cutting machines and bending machines that can process some metal cutting and bending below 20 mm.

Our company has many years of experience, so we can complete the processing of many shapes of product angles, because we have a lot of spare Angle bending molds. This is our advantage.

Usually for thin products we use laser cutting and bending to complete, can save a lot of cost.

Optical cutting is the use of focused high power density laser beam to irradiate the workpiece, so that the irradiated material quickly melt, vaporize, ablate or reach the ignition point, so as to achieve workpiece cutting.

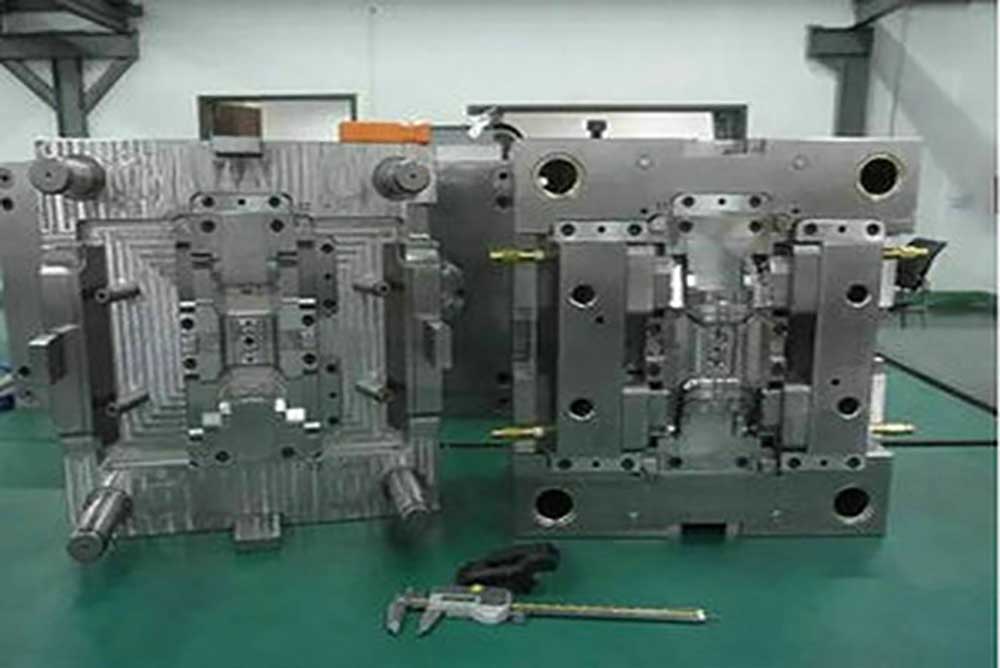

Silicone Injection Molding

We do injection plastic productsand silicone products, and we can produce molds by ourselves, so we are competitive, plastic and silicone products are used in electronic appliances, beauty, home appliances and other fields.

We can do simple molds, reduce mold prices or 3D printing molds, we have rich experience.

Injection molding is the use of plastic thermophysical properties, the material from the hopper into the barrel, the barrel outside the heating ring heating, so that the material melt, according to the shape of the mold cooling molding

Electric Welding

We have experienced welding technicians, we can do ordinary welding and argon arc welding and laser welding, as well as we have matching robot welding process.

we can do welding testing, pressure test, air test, water pressure test, to ensure the quality of welding.

For large quantities of products, we can use robotic welding, which is very cost saving Welding, also known as welding, is a manufacturing process and technology in which metals or other thermoplastic materials such as plastics are joined by heating, high temperature or high pressure. There are many sources of energy for modern welding, including gas flares, electric arcs, lasers, electron beams, friction, and ultrasound.

Community Charging Overall Solution Covers All Application

Business Reception

Business Reception

Payment Method

Payment Method

Raw Material

Raw Material

Drawing Inspection

Drawing Inspection

Give Birth To

Give Birth To

Quality Inspection

Quality Inspection

Ultrasonic Cleaning

Ultrasonic Cleaning

Package

Package

Transport

Transport

We Can Process And Use Materials

Anodizing

Anodizing

Powder Coating

Powder Coating

Electrophoresis

Electrophoresis

Galvanize

Galvanize

Decorative chrome

Decorative chrome

Gild

Gild

Silvering

Silvering

Nitriding

Nitriding

Passivation

Passivation

Sandblast

Sandblast

Electrolysis

Electrolysis

Tin

Tin